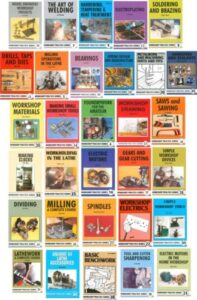

Workshop Practice Complete Series

Workshop Practice Complete Series

Harold Hall was for a number of years the editor of Model Engineers’ Workshop magazine and through its pages, he established himself as a mentor to tyro model engineers worldwide. He is the author of seven books in the indispensable Workshop Practice Complete Series and lives in the Hertfordshire countryside. Harold Hall commenced an industrial apprenticeship in 1950 at the age of sixteen and worked as an electrical control systems engineer for thirty-five years before becoming editor of Model Engineer’s Workshop magazine in 1991. Following retirement in 1995, he has continued to contribute metalworking articles to almost every issue of the magazine published since then. His crafting hobbies extend beyond model engineering to cabinet making, modelling, marquetry and pencil sketching.

You can also read Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat Transfer

Workshop Practice Complete Series Content

- Hardening, Tempering & Heat Treatment

![Workshop Practice Complete Series]()

- Vertical Milling in the Home Workshop

- Screw cutting in the Lathe

- Foundry work for the Amateur

- Milling Operations in the Lathe

- Measuring and Marking Metals

- The Art of Welding

- Sheet Metal Work

- Soldering and Brazing

- Saws & Sawing

- Electroplating

- Drills Taps and Dies

- Workshop Drawing

- Making Small Workshop Tools

- Work-holding in the Lathe

- Electric Motors

- Gears & Gear Cutting

- Basic Bench-work

- Spring Design and Manufacture

- Metalwork and Machining Hints & Tips

- Adhesives & Sealants

- Workshop Electrics Includes planning, fusing, fixtures, fittings & wiring for 240 volt mains electricity.

- Workshop Construction Construction methods and details for building your workshop. Includes layout, planning, tools, cost saving ideas and more.

- Electric Motors in the Home Workshop

- The Backyard Foundry

- Home Workshop Hints & Tips

- Spindles Describes the design, construction and use of a variety of spindles. Milling, grinding and drilling spindles along with unique light gear cutting frame for clock makers.

- Simple Workshop Devices

- CAD for Model Engineers

- Workshop Materials

- Useful Workshop Tools

- Unimat III Lathe Accessories

- Making Clocks

- Lathe work: A Complete Course (Read Review)

- Milling: A Complete Course

- Photo Etching

- Dividing

- Tool & Cutter Sharpening

- Model Engineers’ Workshop Projects

- Bearings

- Grinding, Honing & Polishing

Comments are closed.